Solar Shading and Blackout Systems

- Choose the Right Solution and Save Money and Energy

Introduction

We have been manufacturing solar shading systems since 1938. What started as a way to block light during wartime later evolved into solutions for blocking light to avoid interference with projectors, TVs, and computer screens. Today, the systems we produce are integral to a building's energy efficiency. Whether you want to block light, retain light, or save energy, we have the solution for you.

In this chapter, we will cover the available systems, fabric options, and their appropriate applications. We will also discuss key considerations for planning and provide explanations of technical terms you may encounter. A separate chapter is dedicated to solar shading and blackout control systems.

In addition to meeting traditional needs, such as blocking light to improve image quality and eliminate glare on TVs and computer screens, solar shading has become essential for achieving energy efficiency goals. This is particularly relevant for modern buildings with large glass surfaces, where solar radiation significantly impacts both indoor comfort and energy performance.

Advice and Planning:

Before we move on, we want to emphasize that we offer free advice, planning, and measurement assistance to ensure your project is successful from the start. You don’t need to master everything described in this document (unless you'd like to work with us) to achieve great results. Instead, contact us as early as possible in the process to save time and money.

For a budget estimate: Provide the width and height of your windows and let us know. If you have blueprints, send them along, and we’ll take care of the rest.

Shortcuts in This Document:

Choosing a System

Inside, Outside, or Both?

To determine which system(s) to invest in, you must first decide whether the shading will be installed on the interior, exterior, or both.

- Interior Solar Shading: To prevent glare from the sun and heat loss during colder periods, solar shading is traditionally installed on the inside. Positioned indoors, it is protected from weather and wind and is easy to operate, either manually or electrically. However, it is important to note that heat that has already entered through the glass due to sunlight cannot be removed by an interior shading system. Instead, it must be ventilated or cooled using mechanical ventilation or air conditioning. Interior solar shading can also consist of multiple layers, such as a blackout fabric, a solar protection fabric, and a curtain.

- Exterior Solar Shading: To limit solar heat gain and reduce the need for expensive cooling, solar shading should be installed on the exterior of the windows. This prevents heat from penetrating through the glass surfaces. Exterior shading is most beneficial during the summer months when temperatures are high. During colder seasons, however, it is more energy-efficient to maximize the use of sunlight to warm the interior of the building. Exterior solar shading is exposed to wind, rain, and freezing temperatures. Therefore, it requires controls to regulate when the shading system can be raised or lowered. This typically necessitates a control system connected to sensors that measure sunlight, wind, and temperature. You can find more details about control systems in the dedicated chapter. Additionally, exterior shading systems require guides to secure the fabric and bottom bar in place during gusty conditions.

- Combined Interior and Exterior Shading: The most comprehensive solution is, of course, to have solar shading installed both on the interior and exterior. This allows you to take advantage of the benefits of both systems, achieving both energy efficiency and comfort.

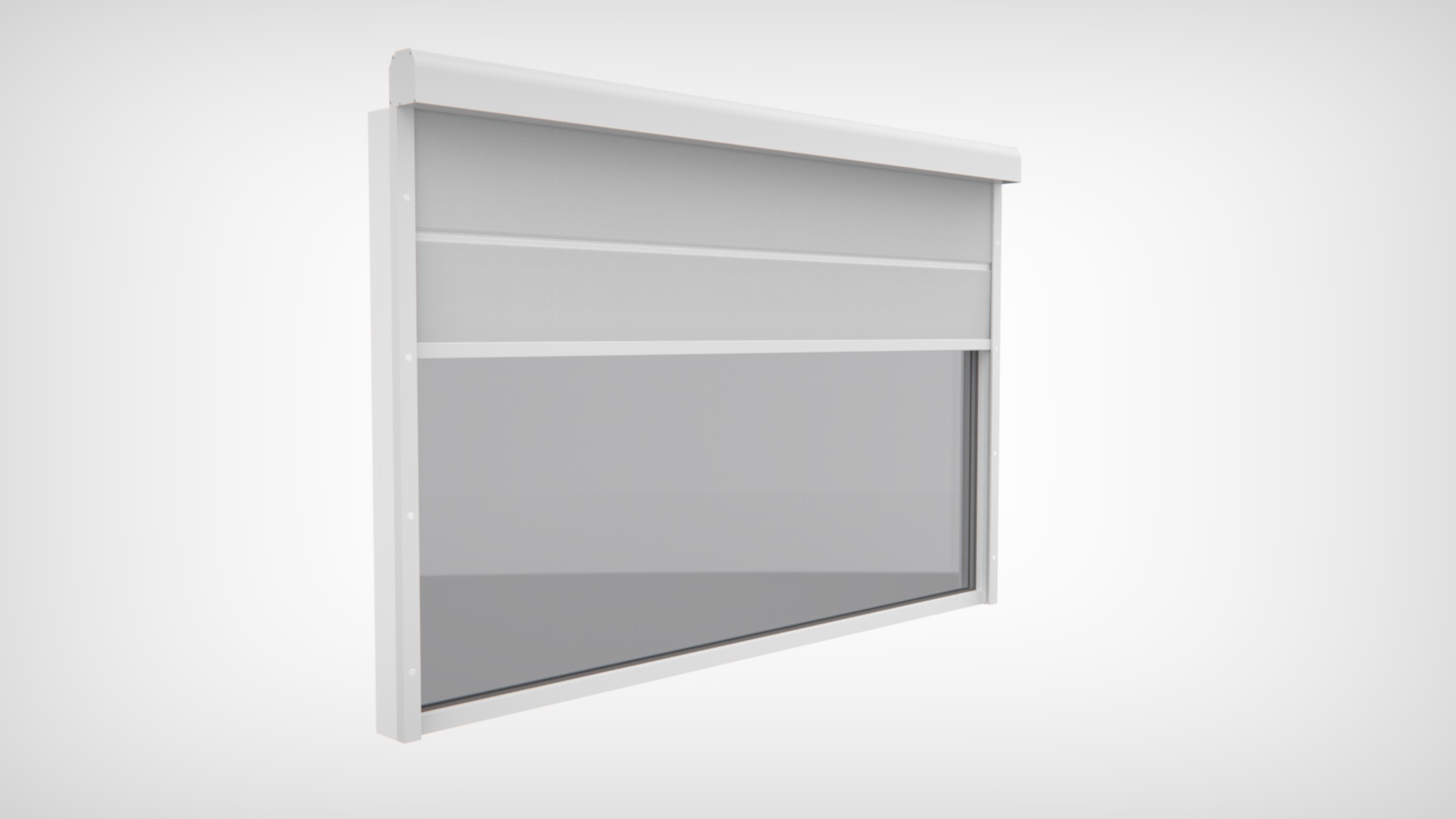

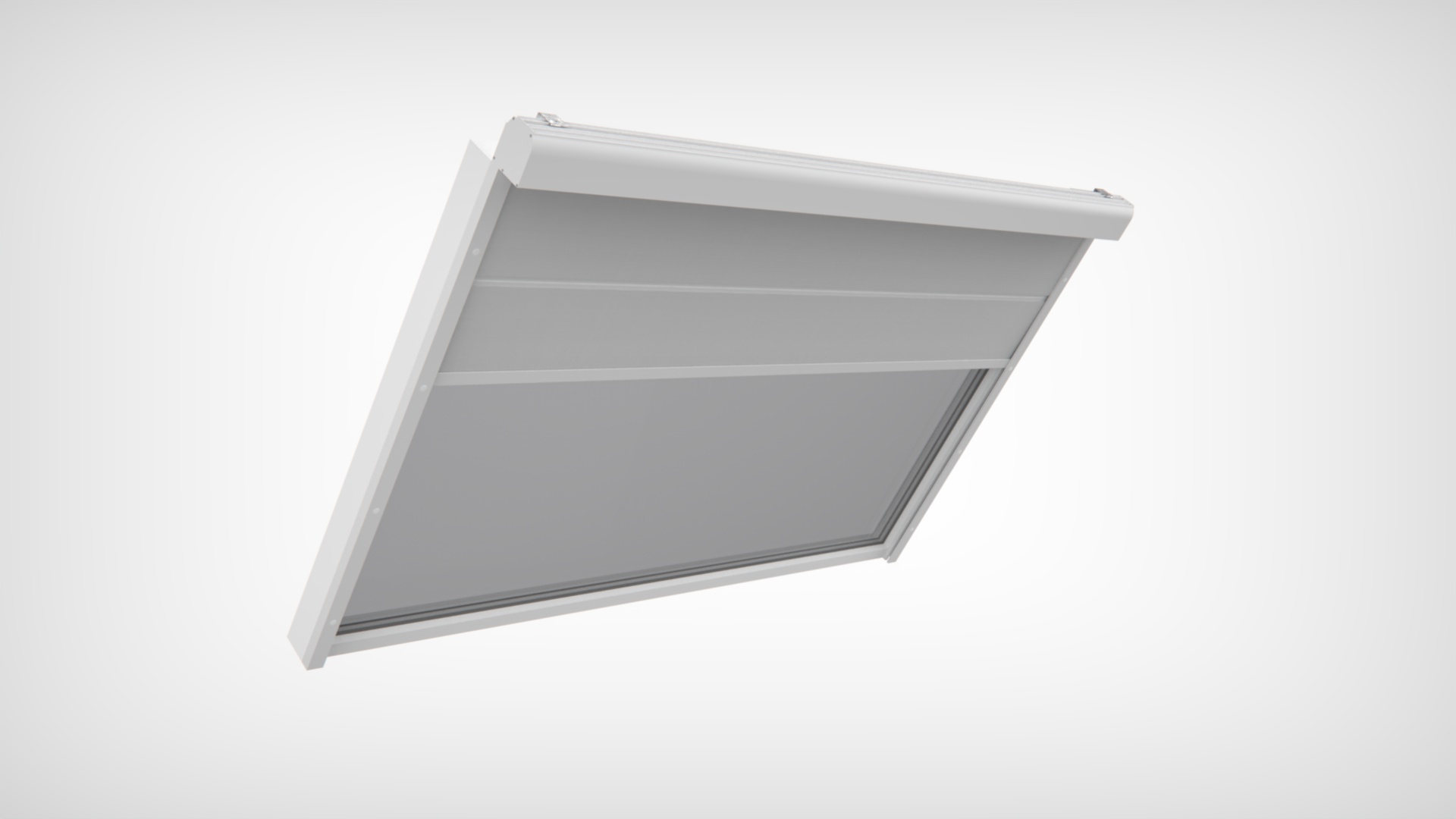

Vertical Systems

Vertical systems are typically mounted with a roller mechanism above the window, allowing the fabric to be rolled down to cover the window. For 100% blackout or exterior installations, the system is equipped with guides, also known as channels. In interior systems, the channels prevent light from entering around the sides of the blackout fabric. In exterior systems, the channels hold the fabric and bottom bar in place during windy conditions. For larger systems, battens may also be required to prevent the fabric from slipping out of the channels. This can occur indoors when thermal expansion of trapped air, caused by solar heat, affects the system. Battens are support rods attached to the fabric to add stiffness and stability.

Horizontal systems

Horizontal solar shading systems are typically used to protect against sunlight entering through skylights, atriums, and lanterns. They come in two variations: one with a motorized roller on one side and another roller on the opposite side of the skylight. One roller holds the fabric, while the other holds cables attached to the fabric. The cables pull the fabric across the skylight to cover it. The other variation has both rollers on the same side of the skylight, with pulleys on the opposite side where the cables are redirected. The result is roughly the same, but the two systems suit different installation situations. Both motors are connected to a shared control box, ensuring synchronized movement and keeping the fabric taut and smooth when fully extended.

Inclined systems

Systems installed at any imaginable angle between fully vertical and fully horizontal are considered inclined systems. For angles up to approximately 30 degrees, vertical systems with guides and battens are used. When the angle becomes more horizontal, horizontal systems are gradually adapted for inclined installation.

Choosing a Fabric

Choosing a fabric involves considering more than just color and appearance. Since energy efficiency is important, it may be necessary to determine how much heat the fabric and window glass together can allow to pass through (referred to as G-total). You may also need to consider safety aspects, such as flame resistance, and environmental factors, such as the presence of PVC and recyclability.

Before we get into the details, fabrics are generally divided into two types:

- Blackout Fabrics:

Composed of three layers: a front layer, a backing material, and an intermediate "blackout layer" that effectively blocks light. - Solar Protection Fabrics:

Available in various types with different openness factors and coatings.

Screen Fabrics: Coated with materials like aluminum for high reflectivity and good openness.

Climate Fabrics (FFA Fabrics): Feature high Rs values and an openness factor (OF) of around 3–4%.

The Importance of Thickness:

The thicker the fabric, the better its insulation properties (specified in technical data as a Ts value).

Color Selection:

In addition to their aesthetic role and impact on a building's visual appearance, colors have several practical and strategic aspects to consider:

- Matching the facade and surroundings: The color should harmonize with the building's facade or the wall where the shading is installed, as well as the surrounding environment, to create a cohesive and professional impression.

- Organizational branding: Color choices can enhance an organization's or business's brand identity by reflecting corporate colors or logos.

- Building permits and regulations: In some municipalities, outdoor shading systems require building permits, and color choices may be influenced by local regulations or requirements to blend with the cityscape. This should be considered early in the planning process.

- Exterior surfaces: The outside of the fabric should be white or light-colored for better reflection of solar heat.

- Interior surfaces: The inside of the fabric can be black or dark-colored to minimize reflections, which is particularly important for screen visibility in meeting rooms.

We have access to the entire market range, offering numerous samples and data sheets for blackout and solar protection fabrics.

Considerations for Planning

General

Advice and Planning:

We offer free advice and measurement assistance to ensure your project is executed correctly from the start. Contact us as early as possible in the process to save time and money.

For a Budget Estimate:

Provide the width and height of the window to be shaded. If available, send blueprints, and we will handle the rest.

Ready-Made Products:

For the most common models and sizes, we offer fully assembled products that are ready for installation.

Important Details Before Production

- Fabric dimensions (Width x Height)

- Fabric type (Color and Model)

- Housing dimensions and color.

- Electrical operation with left- or right-mounted motor.

- Manual operation with crank or spring.

- For special models, such as bottom-up shading systems, request additional information.

System Placement

Common Mounting Options:

- Inside the window recess.

- Surface-mounted.

- Above suspended ceilings with a slot in the ceiling.

Please Note:

- If the window opens inward, this must be accounted for during planning.

- Emergency exit doors must never be blocked. In these cases, it is recommended to install the shading directly on the door.

- The unit must be installed perfectly level to avoid uneven fabric winding or creases.

When Placing an Order

Always specify the following when placing an order:

SVisible fabric dimensions (Width x Height).

- Add approximately 300 mm to the height for attachment to the roller.

- If no fabric dimensions are provided, the system will be delivered at the maximum dimensions for the selected article number.

Width measurements: Add 135 mm for attachment and 55 mm for plug connection.

- The plug connection can be omitted if the cable is connected directly to a relay box or junction box.

Technical Terms

Below is a collection of commonly encountered terms in the context of solar shading and energy. We’ve also included a fact sheet on how to select the right tubular motor for your application. Please note that we handle all these technical aspects for you to ensure you get the right solution. This information is provided for those who want to learn more.

U- and G-Values:

- U-Value: Indicates the heat loss through a building's surface. A lower value means better insulation.

- G-Value: Total solar energy transmission through glass. Scale 0–1, where 1 means all energy passes through, and 0 means none passes through.

Gtot-Value:

- Represents the total solar energy transmission for glass combined with solar shading, calculated according to ISO 52022-1 or 52022-2 standards.

Ug-Value:

- Heat transfer coefficient measuring the insulating properties of glass. A lower value indicates better insulation.

Glazing Categories:

- A: Single glass (4 mm).

- B: Double glazing with air gap (4 mm).

- C and D: Double glazing with argon and various coatings.

- E: Triple glazing with coatings and argon (4 mm).

Ts-Value:

- Indicates the amount of heat that passes through the fabric.

- Ts 0% = No heat passes through.

Tf-Value:

- Indicates the amount of light that passes through the fabric.

- Tf 0% = No light passes through.

Rs-Value:

- Indicates the amount of light reflected by the fabric.

Rv-Value:

- Indicates the amount of heat reflected by the fabric.

As-Value:

- Indicates the amount of light absorbed by the fabric.

Ar-Value:

- Indicates the amount of heat absorbed by the fabric.

Balance Formula:

- T + A + R = 100% of all light and heat.

OF (Openness Factor):

- The ratio of open area to the total surface area of the fabric.

Sound Absorption:

αw / NRC (Noise Reduction Coefficient): Indicates the fabric's ability to absorb sound:

- A: 0,90–1,00 (Excellent sound absorption).

- B: 0,80–0,85.

- C: 0,60–0,75.

- D: 0,30–0,55.

- E: 0,15–0,25 (Low sound absorption).

Tubular motors have a specific torque and rotational speed, expressed as, for example, 15/30, where 15 is the torque in Newton-meters (Nm) and 30 is the speed in revolutions per minute (RPM).

If the radius of the roller is known, you can calculate how much weight the motor can lift.

Weight (kg) = Torque (Nm) x 100 / Roller radius (mm).

For example, with a 60Ø mm roller and a motor specification of 15/30:

15 x 100 / 30 = 50 kg