The Office eXperience

Center now offers all types of solar shading solutions. For the first time ever, there is an exhibition where you can see various options, such as:

The Office eXperience

Center now offers all types of solar shading solutions. For the first time ever, there is an exhibition where you can see various options, such as:

Horizontal solutions – so-called FTS systems up to 10 meters.

- Horizontal wire/band solutions with PX-SHADE.

- Angled solutions with our patent-pending PX-RIBS system.

- Outdoor solutions with our patent-pending RIBS system.

- Traditional manual and motorized solutions.

- Differences between various fabric types.

Whether you are a specifier, builder, or user of solar shading/blackout systems, we have now created the opportunity to experience different solutions for your specific project.

The Office eXperience Center, located at Flygfältsgatan 34 in Skarpnäck, is now also a SOLAR SHADING CENTER.

Why?

The solar shading market has exploded in recent years. It has evolved from being just a general protection against light intrusion and a necessary tool for showing presentations in meeting rooms, to becoming an active part of buildings' energy management systems.

As a manufacturer of blackout solutions since 1938, we have realized that new requirements for solar shading demand new ways of communicating with the market. That’s why we’ve developed our systems to adapt them to the new requirements of solar shading as an integrated part of building energy consumption. We’ve also developed and patented a system, PX RIBS, which simplifies traditional ZIP systems with welded locking bands.

In order for the market to understand and evaluate the characteristics of different solutions before making a decision, we have built our unique visual and acoustic exhibition showcasing all types of solar shading and blackout solutions.

When Are the Different Systems Suitable?

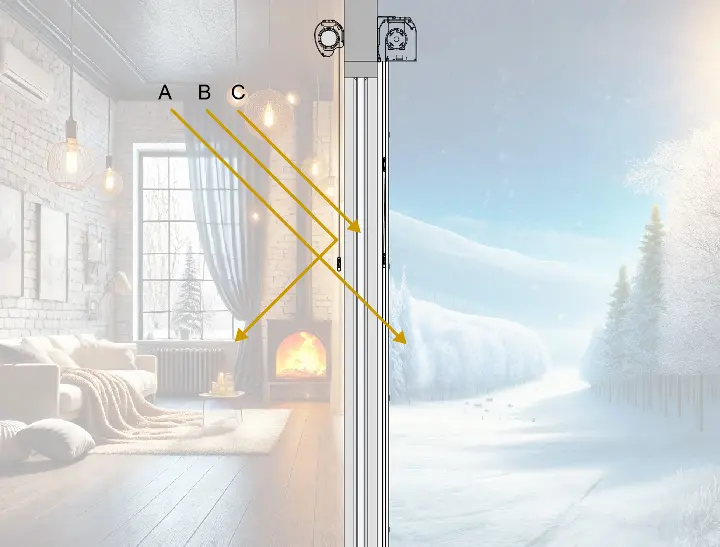

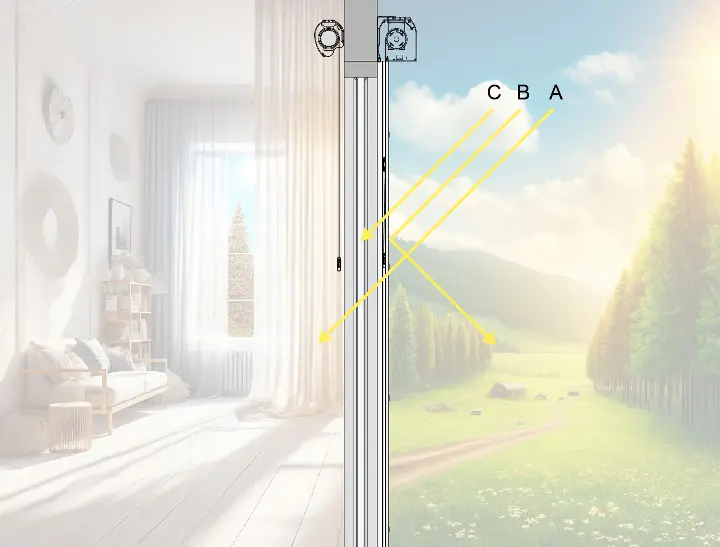

At its core, the choice is between indoor and outdoor installations. An outdoor installation is typically required if the goal is to reduce heat ingress into the building, playing an active role in energy consumption for cooling. In Sweden, this is most relevant in the middle of summer. However, if the goal is to retain heat within the building, such as in autumn and winter, an indoor installation is necessary.

In Winter: Some heat and light (A) radiates out through the windows. Part of it is reflected back into the room by internal solar shading (B), while another portion (C) is absorbed by the glass and insulation between the panes. The heat that passes through the windows is lost – an external solar shading solution cannot return it to the building.

In Summer: Heat and light (A) radiate in through the windows. Some of this radiation is reflected away by external solar shading (B), while a portion (C) is absorbed by the glass. Once the heat has entered the building, it remains – internal solar shading cannot redirect it outside.

Energy always needs to be managed in some way: it is either reflected, absorbed, or transmitted (passed through). The key is to manage it on the correct side of the window.

For general solar shading, an indoor installation is always the solution. The best solution depends on the building’s design, window size, and whether it concerns vertical window sections, horizontal windows, or angled skylights.

Manual or motorized operation is another choice that must be made. Today, fully automated solutions are the most common, and in systems where energy saving is the primary goal, this is essential in order to control the systems based on sunlight, wind, and cold.

This solution key is designed to assist in planning.

Function / System | Spring | Bead Chain | Hand Crank | PX-FTS | PX-SHADE | PX-RIBS | Small | Large |

Width (m) | 3 | 2,4 | 5 | 6 | 4 | 4 | 4 | 6 |

Height (m) | 2 | 2 | 3 | 10 | 8 | 3 | 4 | 6 |

Indoor | x | x | x | x | x | x | x | x |

Outdoor | - | - | - | - | - | x | - | - |

Horizontal | - | - | - | x | x | - | - | - |

Angled | - | - | x | x | x | x | - | - |

Vertical | x | x | x | - | - | x | x | x |

Channel | - | - | o | - | - | x | - | o |

Cover | o | o | o | o | o | o | o | o |

How Does an FTS System Work: PX-FTS?

These systems are designed for horizontal and angled installations. They consist of dual motors and a unique control box that operates the solar shading/blackout by extending one motor via bands or cables. When the entire unit is extended, the second motor tightens the fabric to create a straight surface. The control box allows for adjustment of how much tension is applied to the fabric.

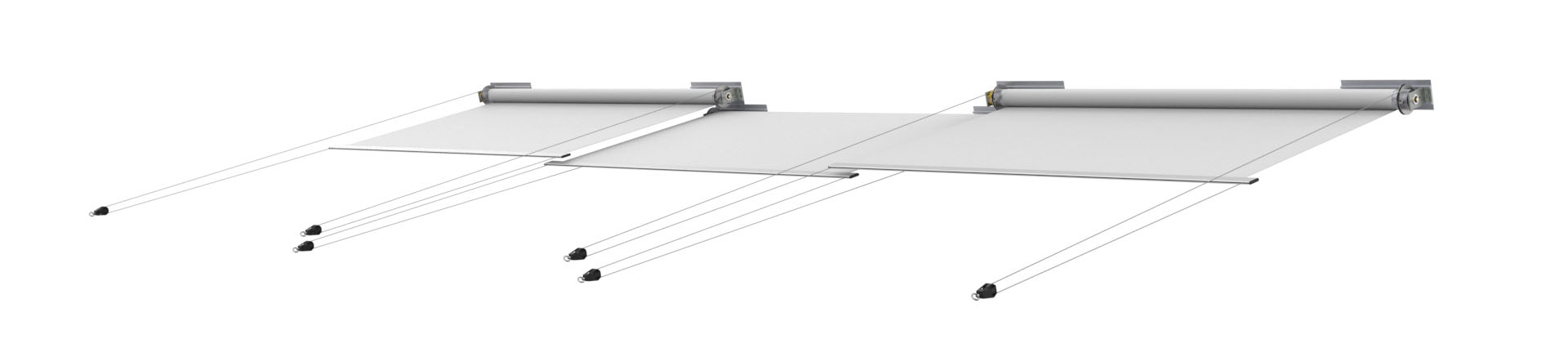

How Does a Line/Wire System Work: PX-SHADE?

This system performs the same task as the FTS system but uses only one motor. As shown in the image, a pulley system is used instead of dual motors. The line is routed through the pulley and tensioned using the same motor that extends the fabric. These systems have some limitations compared to the FTS system regarding fine adjustments, size, and light leakage between units.

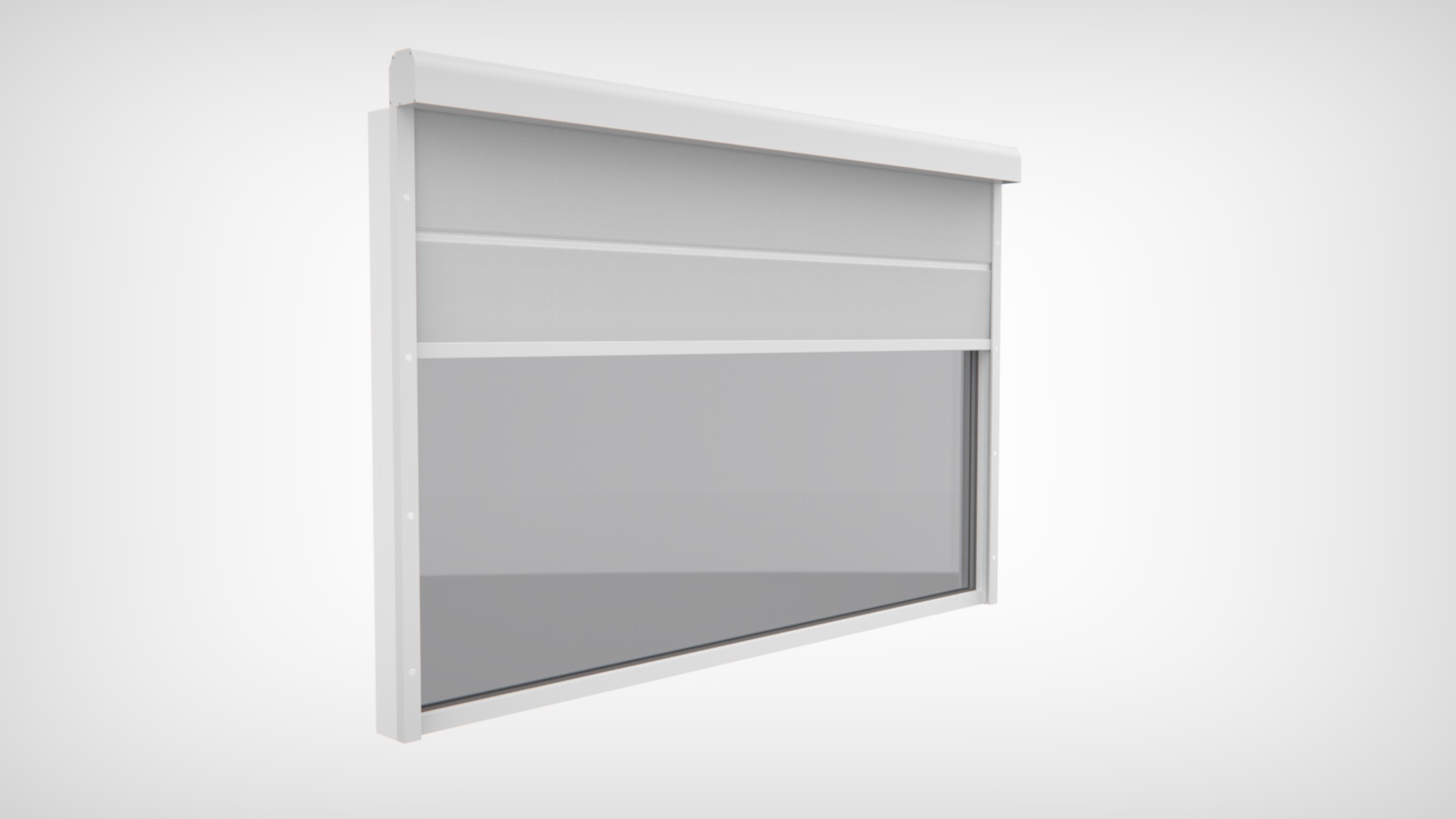

How Does Our New Patented System Work: PX-RIBS?

Traditional ZIP systems are designed for outdoor installations to keep the fabric in place during windy conditions, locking the fabric so that the wind cannot catch it.

For smaller units, a wire is often used between the top and bottom of the window.

Traditional ZIP solutions use welded locking bands held in place by channels. This solution is cumbersome and restrictive in terms of fabric choice, as it requires weldable fabrics with PVC.

We have developed a simpler and more eco-friendly solution, where the fabric is tensioned using guide rails (RIBS) and locked with a simple holder. This makes our solution more flexible and easier to adapt.

How Do Traditional Indoor Solutions Work?

- The most common solution is manual operation with a spring, commonly referred to as a roller blind. This solution is the most cost-effective and well-tested.

- Bead chain is another manual solution but has limitations in terms of size and suitability for public spaces compared to the traditional roller blind.

- Hand cranks are an alternative manual solution for larger units that cannot be handled with a spring or bead chain.

- Motorized Units.

All models are available with motorized options as an alternative to manual solutions. - Channels.

When blackout is required, it is common to install channels for the fabric to run through. These are available for both motorized and manually operated units with hand cranks.

- Covers.

All models can be equipped with covers for protection and to create a more aesthetically pleasing solution.

Choosing Fabric.

Environmental concerns are an important issue for most building projects today, and fabric selection is no exception. Many fabrics contain plastic and PVC, which, as everyone knows, is harmful to the environment, especially PVC, which is both toxic and difficult to break down. We therefore strive to avoid PVC as much as possible when choosing fabrics. However, the selection of fabrics for outdoor use is currently limited, and environmental goals are often at odds with one another.

We categorize fabrics into three basic types.

Blackout

The fabric must be 100% light-blocking, typically achieved through three layers, one of which is a so-called blackout layer. There is a wide variety of options from many different manufacturers. Most manufacturers have adapted their fabrics to be PVC-free today.

Solar Shading

Solar shading fabrics for indoor use differ from those designed to be part of a building’s energy solution. Solar shading fabric limits sunlight while still allowing enough light through to maintain a bright atmosphere.

Energy-Saving Fabrics

Energy-saving fabrics are constructed differently. They are generally dense to reflect sunlight back in outdoor installations and prevent heat from radiating out of the room in indoor installations. To avoid creating a completely dark space where nothing can be seen outside, these fabrics are made with different-sized openings (known as openness factors) and coated with various light-reflecting layers. This is measured in different ways and, together with the glass, is expressed in the G-value (G tot).

It’s important to note that these values are theoretical, calculated according to predefined models. In reality, as everyone knows, the sun’s position changes over time. For example, midsummer provides maximum sunlight exposure, while the winter solstice around December 21st sees minimal sunlight. The calculation models are not directly tailored to Sweden but are global.

How Does Operation Work?

Manual systems require no additional explanation. However, motorized units, particularly those intended to be an active part of a building’s energy management, require careful planning and thorough needs analysis.

Key considerations when planning include:

- Degree of automation: Should each room or unit be controllable by the room’s users or entirely centrally controlled based on environmental requirements?

- Outdoor systems: Should they be automatically regulated by wind, cold, sun, time, or some combination?

- Should the system be adapted to the sun's movement?

- Should the system be integrated with the building’s other systems, such as fire automation?

- Wired or wireless control, or a combination of both?

Generally, systems are built using relay boxes, which typically handle up to four motors. Relay boxes come in different versions. The simplest models are for manual up/down control, while more advanced models are designed for integration into complete systems, controlled via LAN, and sometimes combined with manual control of individual units or rooms.

In more complex systems, data programs are designed based on the needs analysis and controlled via a central unit, such as a PLC system.